Aggregate Processing Plant

Stone Crushing Plant Fixed River Stone with High Efficiency Low Costs

We manufacture Stone Crushing Plant Fixed River Stonewith High Efficiency Low Costs. We devote ourselves to mining machinery many years, and our machines have been exported to South Asia, South America, Africa, Middle East and some other area. We expect be your partner in China.

1. Product Introduction

The stone crushing plant also known as stone production line is a special production line for making sand and aggregates for construction, road and railway industries. It can be used foraggregates and artificial sands of hard limestone, granite, basalt, river pebbles, slag and othermaterials. The designed output is generally 10-500TPH, and it can be equipped with electronic control system, dust removal equipment and so on. The design of the stone crushingplant is designed according to the site survey situation and the actual requirements of the customer, which fully reflects the features of applicability, effectiveness and rationality of the design, low wear, large handling capacity and low operating cost.

2. Specification

No. | Max. feeding size (mm) | Capacity (t/h) | Machine Model | |||||

Vibrating Feeder | Primary Crushing | Secondary Crushing | Vibrating Screen | Belt Conveyor (m) | MotorPower (kw) | |||

1 | 340 | 30 | GZD8030 | PE400×600 | PF1008/ PYD900 | 2YK1235 | 60-90 | 120 |

2 | 340 | 50 | GZD8530 | PE400×600 | PF1008/ PYB900 | 3YK1235 | 100-130 | 140 |

3 | 420 | 80 | GZD9636 | PE500×750 | PF1010/CS75 | 3YK1545 | 130-160 | 200 |

4 | 480 | 100 | GZD9638 | PE600×900 | PF1210/CS160 | 3YK1545 | 140-180 | 280 |

5 | 560 | 150 | GZD1142 | PE750×1060 | PF1214/ CS160 | 3YK1854 | 200-240 | 300 |

6 | 630 | 200 | GZD1142 | PE750×1060 | PF1315/ CS240 | 3YK1860 | 200 | 350 |

7 | 630 | 250 | GZD1149 | PE750×1060 | PF1214*2/ CS160*2 | 3YK2160 | 200 | 400 |

8 | 630 | 300 | GZD1249 | PE900×1200 | PF1315*2/ CS240*2 | 3YK2160 | 250 | 450 |

9 | 700 | 350 | GZD1349 | PE1000×1200 | PF1315*2/ CS240*2 | 3YK2460 | 250 | 500 |

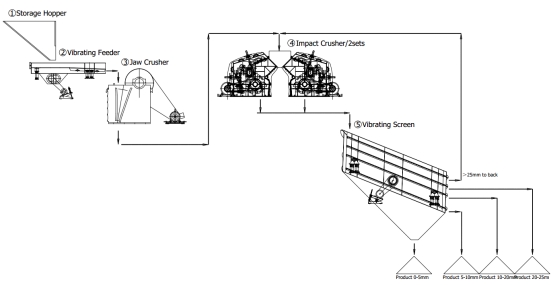

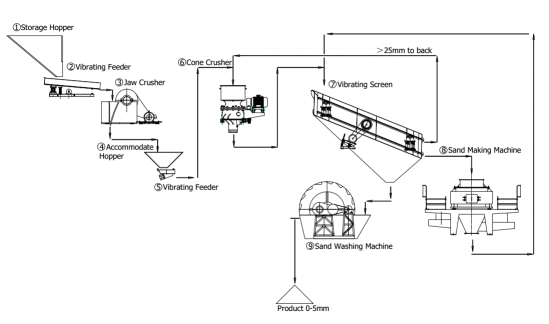

3. Flow Chart

First of all, the stones are uniformly fed into the coarse crusher (generally the jaw crusher) by the vibrating feeder for primary crushing, and the crushed stones are transported by the belt conveyor to the secondary crusher (generally fine jaw crusher, cone crusher or impact crusher)for further crushing. The crushed stones from secondary crusher enter the vibrating screen and are separatedinto different specifications. The stones that meet the size requirements are sent to the finished products pile by the belt conveyor. The stones that do not meet the size requirements are returned to the secondary crusherfor recrushing whichform a closed circuit.

The flow for stone crushing plant:(Hopper)->Vibrating Feeder ->Jaw Crusher ->Fine Jaw Crusher /Impact Crusher /Cone Crusher ->Vibrating Screen ->(Products). The machines are connected by chutes or belt conveyors.

The flow for sand making plant:(Hopper)->Vibrating Feeder->Jaw Crusher ->Fine Jaw Crusher /Impact Crusher /Cone Crusher ->Sand Making Machine ->Vibrating Screen ->Sand Washing Machine->(Sands). The machines are connected by chutes or belt conveyors.

4. Feature

1. The stone crushing plantis highly automated.The complete line requires almost no manual operation except for the startup and shutdown and regular maintenance.

2. High efficiency, low operating costs, large output, high profits.

3. The products have uniform particle sizes, good shape and reasonable grading, which meets the requirements of high-speed materials.

4. It can be equipped with dust removingequipment to reduce environmental pollution.

5. Professional design.Proper machine combination and reasonable layoutmake the plant have small floor space, high economic returns and low powder percentage.

5. Delivery Site

6. Working Site

7. Latest News

8. Recommendation

1. Jaw Crusher

2. Cone Crusher

3. Vibrating Screen

Submit your inquiry and we will make prompt response with professional printing solutions.