We manufacture Hydrocyclone Mini Cone Polyurethane Sand Separator for Solid Liquid. We devote ourselves to mining machinery many years, and our machines have been exported to South Asia, South America, Africa, Middle East and some other area. We expect be your partner in China.

1. Product Introduction

Hydrocyclone is a kind of classifying equipment that utilizes the difference in density between minerals for sorting. It has the characteristics of good cost-performance, small floor space, high sorting efficiency and easy disassembly, so it is widely used in grinding classification, slurry concentration, sewage treatment, oil-water separation and other industries. When used for grinding classification, the joint unit is usually selected, which greatly increases the processing capacity of the equipment.

2. Features

1. Personalized design. According to working conditions and material properties, different wear-resistant materials and different structures are selected to achieve the most ideal sorting effect.

2. Simple structure, easy operation, small footprint and high capacity, greatly shortening the construction period and reducing operating costs.

3. For the feed port and the outlet spigot, hard alloy, hard ceramic, silicon carbide and other special materials can be used as wear parts according to customers’ requirements.

4. It can achieve zero discharge of wastewater, whichdoes not pollute the environment, and saves water resources and social production costs.

3. Specification

Model | Internal dia. (mm) | Inlet pressure (MPa) | Capacity (m³/h) | Cut size (μm) |

FX840 | 840 | 0.04-0.15 | 500-900 | 74-350 |

FX710 | 710 | 0.04-0.15 | 400-550 | 74-250 |

FX 660 | 660 | 0.04-0.15 | 160-450 | 74-220 |

FX610 | 610 | 0.04-0.15 | 200-300 | 74-200 |

FX500 | 500 | 0.04-0.2 | 140-240 | 74-200 |

FX400 | 400 | 0.04-0.2 | 100-170 | 74-150 |

FX350 | 350 | 0.04-0.2V | 70-160 | 50-150 |

FX300 | 300 | 0.04-0.2 | 45-90 | 50-150 |

FX250 | 250 | 0.04-0.3 | 40-80 | 40-100 |

FX200 | 200 | 0.04-0.3 | 25-40 | 40-100 |

FX150 | 150 | 0.04-0.3 | 14-35 | 20-74 |

FX125 | 125 | 0.04-0.3 | 8-20 | 20-50 |

FX100 | 100 | 0.04-0.3 | 8-20 | 20-50 |

FX75 | 75 | 0.1-0.4 | 4-10 | 10-40 |

FX50 | 50 | 0.1-0.4 | 2-5 | 7-40 |

FX25 | 25 | 0.1-0.6 | 0.3-1 | 5-20 |

FX10 | 10 | 0.1-0.6 | 0.05-0.1 | 1-5 |

4. Structure and Working Principle

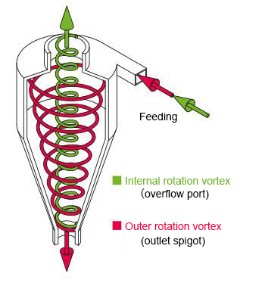

A hollow cylinderand an inverted vertebral body constitute the working cylinder of the hydrocyclone. In addition, there are feed pipes, overflow pipes, outlet spigotand overflow conduit.

The basic principle is to use the density difference of the mixture to finish selection under the action of centrifugal force. The mixture is tangentially directed into the cyclone at a certain pressure and forced into a rotary motion. Among them, the coarse-grained material is subjected to a large centrifugal force, and moves in the outer pulp with a large radius of gyration. However, the fine materialcannot overcome its centrifugal buoyancy for smaller centrifugal force, so it moves in the innerpulp. The cross-sectional area of the cone is continuously reduced, and the slurry containing a large amount of fine particles in the inner layer is forced to move upward and finally discharged from the overflow pipe. The coarse particles of the outer layer movedownwardsand are discharged from the outlet spigot.

5. Pictures

6. Working Site