Mineral Separation Plant

We manufacture Slurry PumpSubmersible CentrifugalIndustrial for Mining Sludge Dredging. We devote ourselves to mining machinery many years, and our machines have been exported to South Asia, South America, Africa, Middle East and some other area. We expect be your partner in China.

1. Product Description

ZJ series slurry pump is a kind of wear-resistantand anti-corrosion equipment developed according to the increasingly complex and special working conditions of chemical, coal, building materials and other industries. The flow passage componentsof the machine are made of high-chromium wear-resistant alloy, which has corrosion resistance and high wear resistance. Therefore, it is mainly used for conveying abrasive slurry containing solid particles, such as slime, pulp, concentrator tailingsand so on. The machine has the advantages of reliable operation, convenient maintenance, high efficiency and energy saving, which makes it the best choice for dealing with abrasive slurry.

2. Features

1. The ZJ series slurry pump adopts high quality materials. The flow passage componentsis made of high-chromium wear-resistant alloy, which has excellent impact resistance, high wear resistance and corrosion resistance, which greatly prolongs the service life.

2. The pump body and pump cover equipa replaceable wear-resistant alloy lining that can be used until wear-through, which extends maintenance cycle and reduces operating costs.

3. Flexible transmission form. There are direct connection, belt, hydraulic, frequency control, etc., transmission forms can be selected according to customers’ requirements.

4. Energy saving, high efficiency, reasonable structure, low noiseand low vibration.

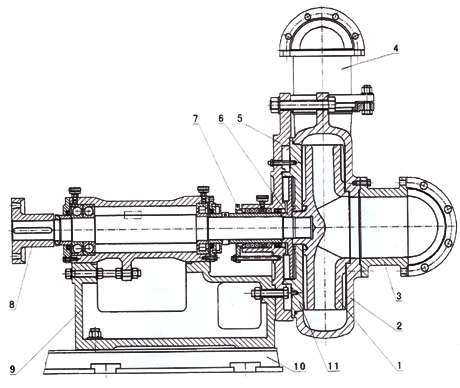

3. Structure

1. Impeller 2. Volute Casing 3. Inlet

4. Outlet 5. End Cover 6. Expeller

7. Disassembly Ring 8. Coupling 9. Support

10. Base 11. Liner Plate

4. Technical Data

Model | Flow (m³ /h) | Head (m) | Speed (rpm) | Passing Size (mm) | Weight (kg) |

300ZJ-A110 | 764-1700 | 33.1-78.0 | 400-590 | ≤49 | 6300 |

300ZJ-A100 | 619-1826 | 27.2-67.1 | 400-590 | 5750 | |

300ZJ-A95 | 589-1735 | 24.6-60.6 | 400-590 | 5600 | |

300ZJ-A90 | 632-1844 | 33.4-78.0 | 500-730 | ≤45 | 5000 |

300ZJ-A85 | 596-1742 | 29.9-69.6 | 4850 | ||

300ZJ-A70 | 647-2333 | 16.7-76.8 | 500-980 | ≤51 | 4150 |

300ZJ-A65 | 601-2166 | 14.4-66.2 | 4000 | ||

300ZJ-A56 | 403-1568 | 10.0-48.0 | ≤54 | 2950 | |

250ZJ-A96 | 504-1470 | 39.9-91.0 | 500-730 | ≤38 | 5200 |

250ZJ-A90 | 473-1378 | 35-80 | 5150 | ||

250ZJ-A85 | 384-1504 | 31.4-129.8 | 500-980 | ≤42 | 4686 |

250ZJ-A83 | 375-1468 | 30-123.8 | 4665 | ||

250ZJ-A80 | 316-1415 | 27.8-115 | 4630 | ||

250ZJ-A78 | 352-1380 | 26.5-109.3 | 4620 | ||

250ZJ-A75 | 301-1480 | 22.3-98.4 | ≤40 | 3600 | |

250ZJ-A73 | 293-1441 | 21-93.2 | 3590 | ||

250ZJ-A70 | 288-1380 | 19.4-85.7 | 3570 | ||

250ZJ-A68 | 280-1341 | 18.3-80.9 | 3560 | ||

250ZJ-A65 | 305-1249 | 15.4-68.5 | 3550 | ||

250ZJ-A63 | 295-1211 | 14.5-64.3 | 3540 | ||

250ZJ-A60 | 281-1152 | 13.1-58.4 | 3530 | ||

200ZJ-A75 | 230-900 | 24.0-103.7 | ≤31 | 3210 | |

200ZJ-A73 | 223-876 | 22.7-98.2 | 3190 | ||

200ZJ-A70 | 240-950 | 19.9-85.8 | 3160 | ||

200ZJ-A68 | 233-923 | 18.8-81.0 | 3140 | ||

200ZJ-A65 | 240-950 | 17.2-74.0 | ≤35 | 2450 | |

200ZJ-A63 | 233-921 | 16.1-69.5 | 2430 | ||

200ZJ-A60 | 223-870 | 14.6-64.0 | 2400 | ||

200ZJ-A58 | 215-841 | 13.7-59.8 | 2380 | ||

150ZJ-1-A70 | 95-400 | 20-91 | 490-980 | ≤37 | 2985 |

150ZJ-1-A65 | 154-600 | 18.9-78.5 | 500-980 | ≤27 | 2100 |

150ZJ-1-A63 | 149-582 | 17.7-73.7 | 2050 | ||

150ZJ-1-A60 | 137-550 | 15.4-64.5 | 1800 | ||

150ZJ-1-A58 | 132-532 | 14.4-60.3 | 1780 | ||

150ZJ-1-A55 | 126-504 | 12.9-54.2 | 1760 | ||

150ZJ-1-A50 | 117-460 | 9.9-45.5 | 1630 | ||

150ZJ-1-A48 | 112-442 | 9.1-41.9 | 1610 | ||

150ZJ-1-C42 | 142-550 | 12.1-64 | 700-1480 | ≤35 | 1550 |

100ZJ-1-A50 | 86-360 | 20.2-101.6 | ≤19 | 1440 | |

100ZJ-1-A46 | 79-331 | 17.1-86 | ≤19 | 1310 | |

100ZJ-1-A42 | 68-275 | 14.6-71 | ≤20 | 1078 | |

100ZJ-1-A39 | 63-255 | 12.6-61.2 | 1060 | ||

100ZJ-1-A36 | 61-245 | 9.1-48.6 | 890 | ||

100ZJ-1-A33 | 57-225 | 7.7-40.8 | 870 | ||

80ZJ-1-A52 | 58-240 | 24-110 | 730-1480 | ≤21 | 1080 |

80ZJ-1-A42 | 61-260 | 13.3-70.6 | 700-1480 | ≤13 | 970 |

80ZJ-1-A39 | 56-241 | 11.4-60.9 | 945 | ||

80ZJ-1-A36 | 45-190 | 10.0-51.5 | 885 | ||

80ZJ-1-A33 | 41-174 | 8.4-43.0 | 860 | ||

65ZJ-1-A30 | 23-80 | 7.4-35.8 | ≤11 | 820 | |

65ZJ-1-A27 | 20-72 | 6.0-29.0 | 795 | ||

50ZJ-1-A50 | 25-110 | 26-108 | 730-1480 | ≤13 | 1400 |

50ZJ-1-A33 | 12-50 | 8-43 | 730-1480 | 900 | |

40ZJ-1-A19 | 7-34 | 12-57 | 1050-2930 | ≤11 | 270 |

40ZJ-1-A17 | 5-20 | 7.0-33.6 | 1390-2890 | ≤10 | 430 |

150ZJL-35 | 119-364 | 4.4-17.8 | 590-980 | 900 | |

100ZJL-34 | 130-385 | 10.7-29.0 | 970-1480 | 850 | |

80ZJL-36 | 69-201 | 14.0-45.5 | 970-1480 | 660 | |

65ZJL30 | 20-105 | 6-35 | 730-1470 | ≤8 | 530 |

50ZJL-20 | 12-39 | 2.6-10.2 | 940-1440 | 250 | |

40ZJL-25 | 5-26 | 4-22 | 730-1440 | ≤8 | 260 |

40ZJL-21 | 5-26 | 3.5-17 | ≤10 | 230 |

5. Pictures

6. Working Site

Submit your inquiry and we will make prompt response with professional printing solutions.