制砂设备

Sand Collecting MachineCollector Fine Sludge Sand Recovery Machine

We manufacture Sand Collecting MachineCollector Fine Sludge Sand Recovery Machine. We devote ourselves to mining machinery many years, and our machines have been exported to South Asia, South America, Africa, Middle East and some other area. We expect be your partner in China.

1. Product Introduction

Sand Collecting Machine is a advanced machine produced by our Sankay company,we design it according to the actual situation of sand powder,now Fine Sand Recovering machine had been widely used in hydropower station’s processing system, glass raw material processing system, artificial sand production line,coarse coal slurry recovery and environmental protection engineering, etc. It can efficiently solve the fine sand recovering problems.

2. Features

1.The sand collecting machine can reach 95%,spare parts adopts special material to strengthen,which extend its service life.

2.Vibrating screen adopted polymer polyurethane screen meshes,which make its lifespan longer than before.

3.It is a multi-purpose machine, and integrates all the functions of the fine sand recovery machine and the sand washing machine, which can realize sand washing, fine sand recovery, etc.

4.Double screen mesh design, it can be adjusted according to different requirements and realize sand classification.

5.80%-90% of the fine particles in the total amount could realize recycling, other machines cannot compare to with it.

6.Small body, it is easy to install and migrate.

3. Working Principle

Thesand collecting machine is composed of motor, sand pump, centrifugal separator, TS linear dewatering screen, cleaning tank, return tank and so on. When it is working,sand pump put sand water mixture delivered to the centrifugal separator,the concentrated fine sand through sand mouth supply for vibrating screen.After dewatering by vibrating screen,fine sand and water are being separated,small amount fine sand and clay return back to clearing tank to washing,when the tank surface is too high,the product is being discharged. Linear dewatering screen recovers concentration of the material from 70% to 85%. Adjusting the fineness modulus can be achieved by changing the sand pump speed, changing the mortar, adjusting the amount of overflow and changing the sand discharge nozzle. Thereby complete the functions of washing, dehydrating and grading.

4. Technical Parameter

Model | Hydrocyclone Diameter (mm) | Capacity (m3/h) | Pump | Dewatering screen | Weight (kg) | |||

Power(kw) | Size (inch) | Model | Space (m2) | Power (kw) | ||||

L-06-300 | 300 | 30-80 | 11kw | 2.5'' | 06x2.25 | 1.35 | 2x1 | 3945 |

L-08-300 | 300 | 40-100 | 15kw | 3'' | 08x2.25 | 1.8 | 2x1.5 | 4200 |

L-10-350 | 350 | 70-130 | 18.5kw | 3'' | 10x2.25 | 2.5 | 2x1.5 | 4900 |

L-12-550 | 550 | 100-220 | 22kw | 4'' | 12x3.0 | 3.6 | 2x3.0 | 7515 |

L-12-650 | 650 | 120-272 | 30kw | 5'' | 12x3.0 | 3.6 | 2x3.0 | 7833 |

L-14-750 | 750 | 180-350 | 37kw | 6'' | 14x3.0 | 4.2 | 2x3.0 | 9610 |

L--14-750Ⅱ | 750 | 230-430 | 45kw | 6'' | 14x3.75 | 5.25 | 2x5.5 | 11850 |

L-16-900 | 900 | 250-500 | 55kw | 8'' | 16x3.75 | 5.25 | 2x5.5 | 14300 |

BL--16-650 | 2*650 | 300-500 | 55kw | 10'' | 18x3.75 | 6.00 | 2x5.5 | 16700 |

L-18-750 | 2*750 | 400-600 | 75kw | 10'' | 18x3.75 | 6.75 | 2x7.5 | 19680 |

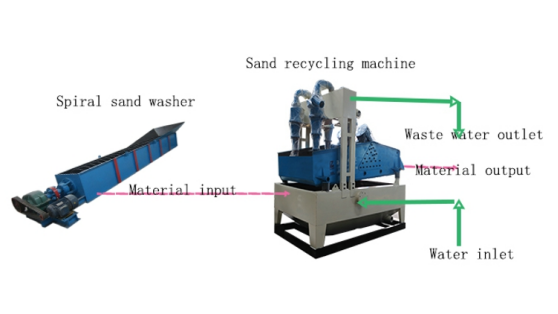

5. Flow Chart

6. Pictures

7. Working Site