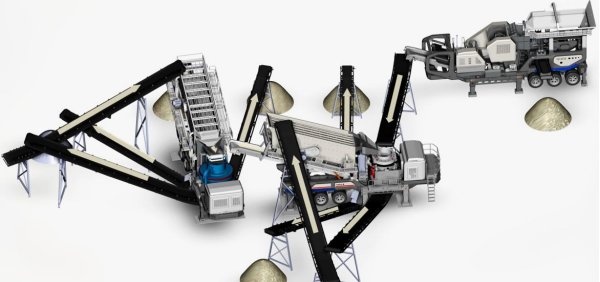

Mineral Separation Plant

Mobile Crushing and Screening Plant Small Combined Semi with High Efficiency Low Costs

We manufacture Mobile Crushing and Screening PlantSmall Combined Semi with High Efficiency Low Costs. We devote ourselves to mining machinery many years, and our machines have been exported to South Asia, South America, Africa, Middle East and some other area. We expect be your partner in China.

1. Product Introduction

The mobile crushing and screening plant is a kind of mobile stone crushing line. It integrates the feeding, crushing, screening and conveying of the stone crushing plant into a movable chassis, which greatly expands the use scope and condition of theplant. According to the customer's requirementson raw material and final products, the mobile crushing and screening plant can be composed of one chassis or two to three independent chassis. In actual use, it can realize single-stage control or multi-stage interlock control, which greatly improves the flexibility of operation and use.

2. Specification

Primary Crushing

Model | MP600 | MP750 | MP900 | MP1060 | MP1200 | MP1300 | |

Transportation Size (mm) | Length | 8600 | 9600 | 11097 | 13300 | 15800 | 9460 |

Width | 2520 | 2520 | 37559 | 2900 | 2900 | 2743 | |

Height | 3770 | 3500 | 3500 | 4440 | 4500 | 3988 | |

Transportation Weight (kg) | Weight | 15240 | 22000 | 32270 | 57880 | 98000 | 25220 |

Jaw Crusher | Model | PE400×600 | PE500×750 | PE600×900 | PE750×1060 | PE900×1200 | PE×300×1300 |

Feed Opening (mm) | 400×600 | 500×750 | 600×900 | 750×1060 | 900×1200 | 300×1300 | |

Discharge (mm) | 40-100 | 50-100 | 65-180 | 80-180 | 95-225 | 20-90 | |

Capacity (m³/h) | 10-35 | 25-60- | 30-85 | 70-150 | 100-240 | 10-65 | |

Vibrating Feeder | Model | GZD8030 | GZD8030 | GZD9638 | GZD1149 | GZD1352 | GZD8030 |

Hopper Capacity (m³) | 3 | 4 | 7 | 10 | 10 | 3 | |

Hopper Width (mm) | 2200 | 2500 | 3000 | 3000 | 3000 | 2200 | |

Belt Conveyor Model | B500×6 | B650×7 | B800×8 | B1000×11 | B1200×13 | B800×7 | |

Secondary Crushing and Screening

Model | MP1010 | MP1210 | MP1214 | |

Transportation Dimension (mm) | Length | 10800 | 12200 | 12500 |

Width | 2480 | 2743 | 2900 | |

Height | 4170 | 4200 | 4200 | |

Transportation Weight (kg) | 28800 | 31500 | 39600 | |

Impact Crusher Model | PF1010 | PF1210 | PF1214 | |

Feed Opening Size (mm) | 400×1080 | 400×1080 | 400×1430 | |

Vibrating Screen Model | 4YK1235 | 4YK1545 | 4YK1848 | |

Model | MC75 | MC160 | MC240 | |

Transportation Dimension (mm) | Length | 10000 | 11200 | 11800 |

Width | 2743 | 2743 | 2840 | |

Height | 4200 | 4200 | 4200 | |

Transportation Weight (kg) | 28400 | 30500 | 22400 | |

Cone Crusher Model | PY900/ CS75 | PY1200/ CS160 | PY1750/ CS240 | |

Max. feeding Size (mm) | 50-110 | 50-145 | 85-215 | |

Discharge Opening (mm) | 10-32 | 15-50 | 20-50 | |

Vibrating Screen Model | 3YK1235 | 3YK1545 | 4YK1860 | |

Belt Conveyor Model | B650×8 | B800×8 | B1000×8 | |

3. Flow Chart

Applicable materials: rocks and oresof various hardness, such as granite, basalt, marble shale, sandstone, quartz, limestone, iron ore, copper ore, manganese ore, coal gangue, non-ferrous metal ore, pebbles and construction wastes, etc.

Application fields: It is used in ore extraction, construction waste recycling, building aggregate production, highway, railway, road and bridge construction and other industries.

Mobile crushing and screening plant: 1.Vibrating Feeder 2.Jaw Crusher3. Impact Crusher or Cone Crusher 4. Vibrating Screen 5. Vibrating Screen Hopper 6. Belt conveyors 7. Control Panel 8. Chassis 9. Generator Set (Optional)

4. Feature

1. Flexiblemove. It can be quickly transferred among different construction sites,which improvesthe utilization rateof the plant; the layout can be adjusted at will according to the needs of the site to save space.

2. Compact and reasonable structure. The reasonable equipment layout and compact chassis greatly reduce the overall transport length.

3. Save costs. All equipments are assembled and commissioned at the factory, and there is no need to construct foundations and supporting facilities, which greatly shortens the installationtime.

4. Complete configuration. The mobile crushing and screening plant is equipped with electronic control system, conveyor system, and optional generator set. No other supporting facilities are required, andit can be put into productionwith power.

5. Flexible combination and easy operation. According to different needs, it can realize single-stage operation or multi-stage interlocking control.

5. Pictures

6. Working Site

4. Latest News

5. Recommendation

1. Jaw Crusher

2. Impact Crusher

3. Vibrating Screen

Submit your inquiry and we will make prompt response with professional printing solutions.